Energy and the Environment

The Energy and Environment Group cover a broad range of research activities with a specific emphasis on addressing the key drivers for industry and the environment. The research areas covered by the group include:

The Energy and Environment Group cover a broad range of research activities with a specific emphasis on addressing the key drivers for industry and the environment. The research areas covered by the group include:

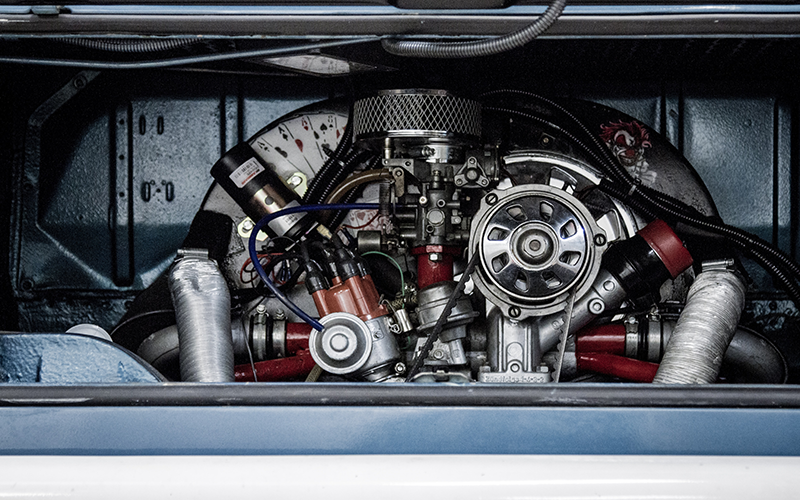

- Combustion and new fuel technologies

- IC Engines

- Turbomachinery and algorithmic development for optimisation

- Pollution, mixing and chemistry in industrial and environmental flows

- High-performance computations applied to industrial and environmental flows

- Refrigeration and air-conditioning

The research group has strong links with leading technology companies and government research laboratories, such as BP, Cosworth Technology, Ford, Jaguar, Lotus Engineering and Shell (IC Engines), ABB Turbo, Ebara Corporation, Sulzer (MAN) Turbo, US Navy’s David Taylor Model Basin (Turbomachinery).

There are also many examples of projects where members of the group work with other universities; for example, the Virtual Centre of Excellence for IC Engines (with Leeds, Loughborough and Oxford), and with ETH Zurich on the design of centrifugal compressors. The group has one spin-off company, Advanced Design Technology Ltd, which is a global leader in the development of advanced Turbomachinery Aerodynamic design codes based on a 3D inverse design approach.

The group have extensive experimental and computational facilities through strategic investment on a departmental and faculty level.

Energy and Environment webinar series

The main mission of the Energy and Environment Research Division at UCL Mechanical Engineering is to promote research, teaching and innovation in a collaborative manner. The Energy and Environment Webinar Series aims to act on three fronts: advance science; develop people; and serve society.

Watch the webinar series on YouTube

Close

Close