Our lab focuses on nanoengineered surfaces, high-resolution 3D printing and novel small-scale manufacturing, nanosensors/devices for healthcare, and micro/nanofluidics and small-scale heat transfer.

Nanoengineered Surfaces

The focus here is on understanding and precision manufacturing of surfaces with controlled wettability and micro/nanotexture. The wettability of the surfaces can be controlled to vary from highly liquid repellent (e.g. superhydrophobic, superoleophobic) to highly wetting (e.g. superhydrophilic, superoleophilic) to surfaces that feature patterns of wettability. Currently, our emphasis is on multifunctional and robust surfaces, which require a rational design including several, often competing, properties. For example, improving the mechano-chemical robustness of superhydrophobic coatings without compromising superhydrophobicity, precise control of surface texture to facilitate both optical transparency and superhydrophobicity, precise and scalable manufacture of surfaces with nanoscale textures for controling nucleation in phase change process (for icephobicity and condensation control) etc. Through rational materials design, we are also making surfaces with an ability to resist bacterial biofilms and/or the ability to smartly regulate the optical and/or electronic properties of surfaces.

Figure: All-organic superhydrophobic coating with mechanochemical robustness and liquid impalement resistance video.

Current applications of nanoengineered surfaces being explored include:

- Superhydrophobic and superoleophobic surfaces

- Steam condensation on wettability engineered surfaces

- Icephobic surfaces

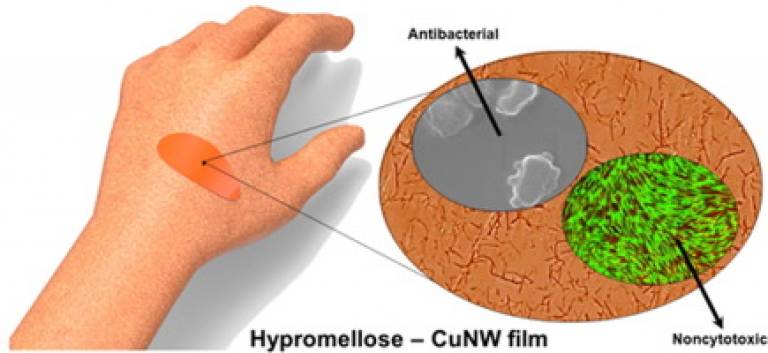

- Antimicrobial surfaces

- Liquid impact resistant surfaces

Relevant Literature

- Singh, V., Men, X., & Tiwari, M. K. (2021). Transparent and Robust Amphiphobic Surfaces Exploiting Nanohierarchical Surface-grown Metal-Organic Frameworks. Nano Lett. doi:10.1021/acs.nanolett.1c00157

- Bagchi, B., Salvadores Fernandez, C., Bhatti, M., Ciric, L., Lovat, L., & Tiwari, M. K. (2022). Copper nanowire embedded hypromellose: An antibacterial nanocomposite film. Journal of Colloid and Interface Science. doi:10.1016/j.jcis.2021.09.130

High-resolution 3D Printing and Novel Small-scale Manufacturing

This line of our research is focused on high-resolution (under 10 micron) 3D printing and light-assisted manufacturing techniques (ranging from photo and soft lithography, electron beam lithography, nanoimprint lithography to laser interference lithography) to newer techniques e.g. block copolymer lithography, electron beam lithography etc. The emphasis in the 3D printing work is to go beyond current commercial systems and enable new precision prototyping capabilities. We are using new developments in this area – both from our laboratory and other internationally leading groups – to make new generation of miniature sensors for wearable and implantable device applications, for new developments in surgical interventions, micro/nanorobotics, and health and care monitoring applications. Most of these works involve close collaboration with clinicians; a majority of these efforts are integrated with our activities as part of Wellcome/EPSRC Centre for Interventional and Surgical Sciences (WEISS).

Figure: Demonstration of 3-D printing at the micro/nano scale

Relevant Literature

Nanoengineering Sensors and Devices for Healthcare

Miniature (nano) sensors for wearable applications have undergone impressive growth recently. A similar transformation in surgical and interventional practice faces a few key challenges: need for rapid sensor prototyping (e.g. using high-resolution 3D printing), materials biocompatibility and/or biodegradability, integration with surgical tools and implantable devices, realisation of multimodal and wireless sensing, etc. We seek to address these challenges and, in close engagement with the WEISS clinicians, focus on the following research drivers:

- Measure physiological parameters such as pressure, pH, temperature, oxygen concentration

- Haptic and tactile sensors and devices

- Microfluidic biosensors

- Integrate sensors on interventional devices

- Explore self-powered sensors for battery-free implantable applications

- Show sensor biodegradability

Figure: Demonstration of a self-poled, deployable MoS2 nanoflower doped PVDF film, which demonstrates excellent piezoelectric (through an energy harvesting nanogenerator) and piezocatalytic functions producing electric charge when subjected to mechanical tapping via triboelectricity.

We are aiming to exploit the above-mentioned sensors in obstetrics, cardiovascular implants, neurosurgery, gastroenterological interventions, and renal transplant applications.

Relevant Literature

Micro/nanofluidics and Small-scale Heat Transfer

The focus and expertise in this line of work is on micro and nanofluidics and small scale heat transfer. There is a joint emphasis on making micro/nanofluidic chips and then using a number of diagnostic tools to characterise flow and transport phenomena in these systems. Examples of our work in this area include:

- Cooling and thermal management for microprocessos, data centres, automotive and avionics

- Sustainable energy-water-environment-health nexus

- Micromixing and process intensification

- Biosensing new developments in diagnostics technologies such as microscale particle image velocimetry, laser induced fluorescence, etc.

Figure: Instantaneous normalized concentration fields in the flow region ranging from −9 < x/D < 13, with the position of fluids interface set to l/W = 0.5 and various gap ratios. The Reynolds number ranges from 678 to 726, i.e. above the critical Re for the onset of vortex-shedding in a channel with similar dimensions and a pin located on the centreline.

Relevant Literature

- Zhang, S., Cagney, N., Lacassagne, T., Balabani, S., Naveira-Cotta, C. P., & Tiwari, M. K. (2020). Mixing in flows past confined microfluidic cylinders: effects of pin and fluid interface offsetting. Chemical Engineering Journal, 125358. doi:10.1016/j.cej.2020.125358

- Zhang, S., Cagney, N., Balabani, S., Naveira-Cotta, C. P., & Tiwari, M. (2019). Probing vortex-shedding at high frequencies in flows past confined microfluidic cylinders using high-speed microscale particle image velocimetry. Physics of Fluids. doi:10.1063/1.5111817

Close

Close