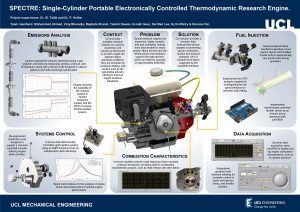

UCL SPECTRE

The UCL SPECTRE team with their prototype.

Team Members

- Mohammed Ahmad

- Viraj Bharadia

- Baptiste Brunet

- Yanish Dewan,

- Avnish Issur

- Sie Man Lee

- Kyrin Mistry

- Nnenne Osi

Supervisors

Dr Midhat Talibi and Dr Paul Hellier

The Project

The main aim of the project was to design and implement cost-efficient modifications to a commercially available donor engine providing the infrastructure for future engine performance analyses.

To achieve this aim, the project was split into four sections:

- Intake

- Exhaust

- in-cylinder

- and control systems.

The outlined aims for the intake system modifications included providing the capability to electronically control the injection of different fuels through two injectors, whilst the exhaust system modifications had the aim of providing the infrastructure required for emissions testing. The in-cylinder system is required to design methods to extract data regarding combustion characteristics.

Finally, the control system has the general aims of creating a platform to track crankshaft rotation, integrate individual components and modifications, as well as establishing an ability to independently control the spark ignition timing of the engine.

The Design

The main features of the design include a port fuel injection system, housing two injectors for liquid and gaseous fuels, a servomotor controlled throttle body and a flush mounted piezoelectric pressure transducer inside of the cylinder head. Moreover we introduced a re-designed crankcase cover with an attached incremental encoder, along with an independently controlled spark ignition system. In addition, we designed an exhaust sensor pipe and soot collection device.

Engine performance analysis, ranging from investigating knock and emissions analysis to varying fuel injection timing, can be performed as a result of completing these modifications, together with an in-house designed engine control unit powered by the LabVIEW software.

With this design we managed to duplicate the functionalities of traditional research engines whilst maintaining a portable form factor, streamlined operation at a lower cost.

Close

Close